The installation of glass lined flange covers is an important step in ensuring the sealing and safety of chemical equipment. The following are the installation steps compiled by the China glass lined flange cover manufacturer for your reference:

1. Preliminary preparation

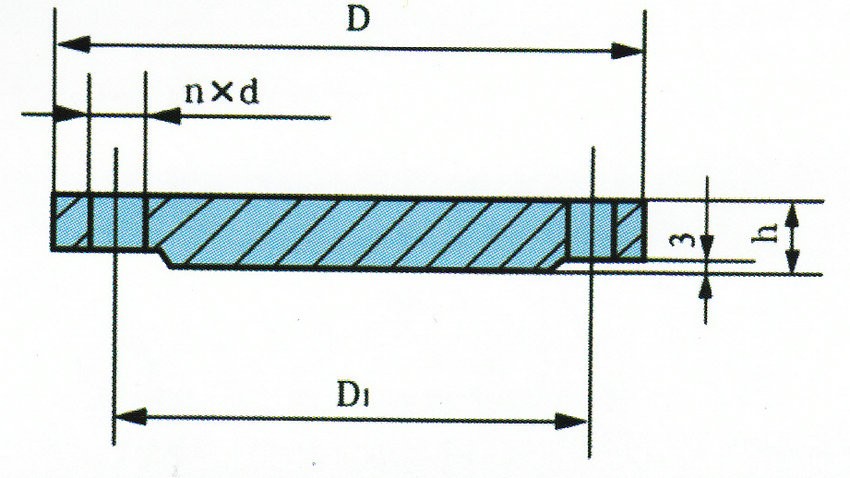

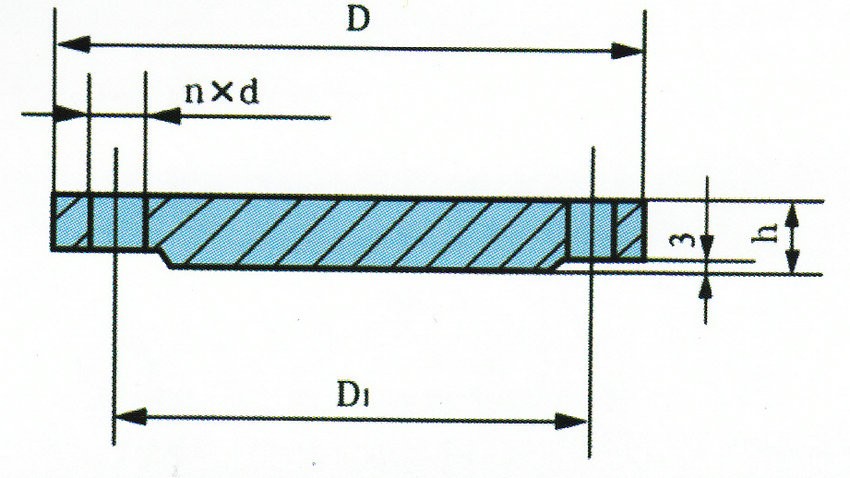

Check the flange cover and equipment: Ensure that the glass lined flange cover matches the size and specifications of the flange of the equipment to be connected, and check whether the surface of the flange cover is flat, smooth, and free of defects such as cracks and bubbles.

Prepare sealing gasket: Select the appropriate sealing gasket according to the working pressure and temperature range of the equipment. Ensure that the sealing surface of the gasket and flange cover is tightly adhered and free of impurities.

Cleaning the flange surface: Before installation, clean the flange surface with a cleaning agent and a soft cloth to ensure that there are no oil stains, dust, or other impurities, so as not to affect the sealing effect.

2. Installation steps

Place the sealing gasket: Place the prepared sealing gasket on the sealing surface of the equipment flange, ensuring that the gasket position is correct and not offset.

Install flange cover: Align the glass lined flange cover with the equipment flange and slowly place it in place. During this process, collision between the flange cover and the flange surface should be avoided to prevent damage to the enamel layer.

Preliminary tightening: Use appropriate bolts and nuts to preliminarily tighten the flange cover in a diagonal cross order. During the tightening process, it should be ensured that the bolts and nuts are evenly stressed to avoid being too tight or too loose.

Check sealing: After initial tightening, apply soapy water or other non corrosive lubricant to the sealing surface of the flange cover, and then tighten the bolts and nuts again. Check the sealing between the flange cover and the equipment flange to ensure no leakage.

Final tightening: On the premise of ensuring sealing, gradually tighten the bolts and nuts to the specified torque value in a diagonal cross order. During this process, a torque wrench should be used for precise control to avoid bolt breakage or flange cover deformation caused by over tightening.

3. Post inspection and maintenance

Regular inspection: During use, the glass lined flange cover should be inspected regularly to ensure that its surface is free of defects such as cracks and bubbles, and the tightening of bolts and nuts should be checked.

Replace the sealing gasket: If the sealing gasket is found to be aged, deformed, or damaged, it should be replaced with a new one in a timely manner to ensure the sealing performance of the equipment.

Cleaning and maintenance: Regularly clean and maintain the glass lined flange cover to remove surface dirt and impurities, in order to extend its service life.

In summary, the installation steps of glass lined flange cover include preliminary preparation, installation steps, and later inspection and maintenance. During the installation process, the operation steps should be strictly followed to ensure the installation quality and safe operation of the equipment. At the same time, regular inspection and maintenance of the glass lined flange cover are also necessary in daily use to promptly identify and address potential issues.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8613386433135

WhatsApp:+8613386433135 Tel: +8613386433135

Tel: +8613386433135