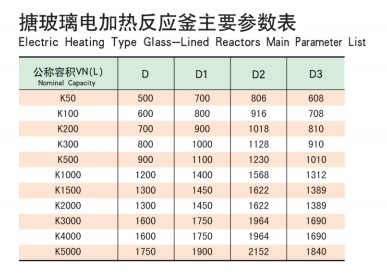

Glass lined electric heating reactor

19/09/26 08:54:09

The enamel glass electric heating reactor is a composite material product made by lining glass containing high silica on the inner surface of a steel container, and firmly adhering it to the metal surface through high-temperature burning. So, it has the dual advantages of glass stability and metal strength, making it an excellent corrosion-resistant equipment that has been widely used in industries such as chemical, petroleum, pharmaceutical, pesticide, and food.

Instructions for using enamel glass electric heating reaction kettle:

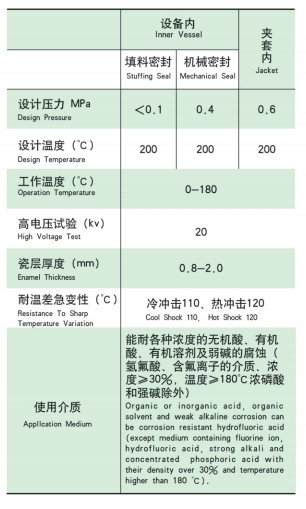

1. The mixing container is used at a temperature of 0 ℃ to 200 ℃, and the storage tank container is used at a temperature of 0 ℃ to 150 ℃;.

2. Equipment temperature resistance and deformation, cold shock: 110 ℃; Thermal shock: 120 ℃. When heating and cooling glass lined equipment, it should be done slowly.

3. Thickness of enamel glass layer: The glass layer thickness of enamel glass equipment is 0.8-2.0mm; The glass thickness of the accessories of the enamel glass equipment is 0.6-2.3mm.

5、耐腐蚀性:能耐各种浓度的无机酸、有机酸、有机溶剂及弱碱的腐蚀(氢氟酸、含氟离子的介质、浓度≥180℃浓磷酸和强碱除外)。

6、不沾性:具有光滑洁净的表面,不宜沾结物料,非常适用于食品及易沾结物料。

搪玻璃电加热反应釜不宜选用于下列介质的反应和贮存,否则将会因腐蚀而较快的损坏。

(1)任何浓度和和温度的氢氟酸;

(2)PH≥12且温度≥百分之100之碱性介质;

(3)浓度在百分之30以上温度≥180℃之磷酸;

(4)酸碱交替之反应;

(5)含氟离子的其它介质。