With the continuous development of industrial production, stainless steel and carbon steel tube heat exchangers, as important heat exchange equipment, have been widely used in various fields. However, due to the complex and ever-changing usage environment, these heat exchangers often face serious corrosion problems, which not only affect the normal operation of the equipment, but also increase the maintenance costs of the enterprise. It is particularly important to take effective anti-corrosion measures in order to extend the service life of heat exchangers and improve operational efficiency. This article will focus on the anti-corrosion measures required for stainless steel and carbon steel tube heat exchangers.

1. Anti corrosion measures for stainless steel tube heat exchangers

1. Material selection:

Choose stainless steel materials with high corrosion resistance, such as binocular stainless steel, Hastelloy, titanium, titanium alloys, etc. These materials have strong chemical stability and can resist the erosion of various corrosive media.

2. Surface treatment:

Polish or passivate the surface of stainless steel to improve its corrosion resistance. Polishing can remove small surface defects and pollutants, while passivation can form a dense oxide film on the surface of stainless steel, further protecting the substrate from corrosion.

3. Structural design:

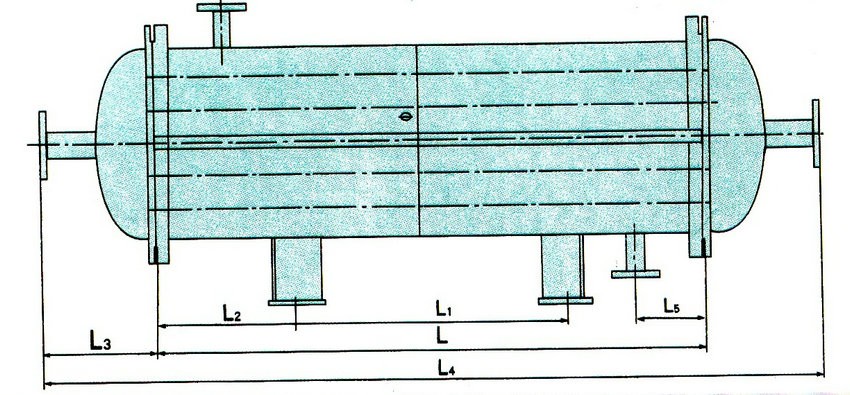

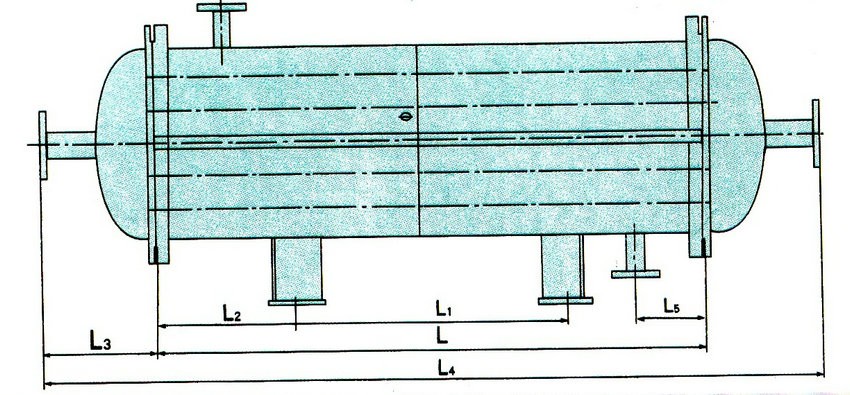

Optimize the structural design of the heat exchanger to avoid the formation of dead corners or gaps where corrosive media is prone to accumulate. For example, a streamlined design can be adopted to reduce fluid turbulence and erosion inside the heat exchanger, thereby lowering the corrosion rate.

4. Coating protection:

Apply a corrosion-resistant coating protective layer on the surface of stainless steel to avoid direct contact between the metal surface and corrosive media. This technical method is economically effective, and the coatings used include organic polymer mixture solutions, oil and solvent resistant coatings, high-temperature coatings, heavy-duty anti-corrosion coatings, etc.

2. Anti corrosion measures for carbon steel tube heat exchangers

1. Electrochemical protection:

Adopt cathodic protection or anodic protection method. Cathodic protection is achieved by applying a direct current power source to transform the anode on the metal surface into a cathode, thereby providing protection; Anode protection is the process of connecting the protected equipment to an external power anode, creating a passivation film on the metal surface to achieve the purpose of protection. However, it should be noted that these two methods consume a large amount of electricity, are expensive, and cathodic protection is difficult to achieve deep inside the tube.

2. Corrosion inhibitor addition:

Adding corrosion inhibitors to corrosive media can greatly reduce or even stop the corrosion of metals. The addition of corrosion inhibitors should be based on the principle of not affecting the production process and product quality.

3. Coating protection:

Similar to stainless steel, the surface of carbon steel can also be coated with a corrosion-resistant coating protective layer. Choose coatings suitable for carbon steel materials and ensure that the coating is uniform and complete to improve its corrosion resistance.

4. Material upgrade and composite structure:

Consider using materials with stronger corrosion resistance for replacement, such as stainless steel carbon steel composite pipes. This composite structure combines the corrosion resistance of stainless steel with the high strength and low cost advantages of carbon steel, making it suitable for working conditions with strong corrosiveness.

5. Welding and heat treatment:

Take appropriate protective measures during the welding process, such as using inert gas shielded welding, to reduce the corrosion tendency of the welding heat affected zone. At the same time, heat treatment is carried out on the welded joints to eliminate welding stress, refine grain size, and improve corrosion resistance.

In summary, the anti-corrosion measures for stainless steel and carbon steel tube heat exchangers need to be comprehensively considered based on their material characteristics and usage environment. By selecting appropriate materials, optimizing structural design, using coating protection, electrochemical protection, or adding corrosion inhibitors, the service life of heat exchangers can be effectively extended and their operating efficiency can be improved.

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong

Address:Room 1202, Detaitang Building, No. 118 Huaguang Road, Zhangdian District, Zibo, Shandong WhatsApp:+8613386433135

WhatsApp:+8613386433135 Tel: +8613386433135

Tel: +8613386433135